09-07-2022

|

4 min read time

Vlint Dusts Off the Hot Asphalt Industry

The production and recycling of asphalt occur at increasingly higher temperatures. For an environmentally friendly process, efficient and reliable dust extraction is required. Vlint is a specialist in this field. We provide advice on the selection and application of heat-resistant filter materials.

Increasing efficiency saves a lot of money

In heavy-duty dust extraction in the asphalt industry, good advice can significantly increase the efficiency of filters. This can save a lot of money. "Often, it involves processes at high temperatures. For this, heat-resistant solutions are needed," says Olaf Schippers, product manager filtration at Vlint. "We help these companies with the selection and application of the right filter materials. Depending on the process conditions, the preference may go to Meta-Aramide, but also to, for example, PPS or Teflon. We also ensure that these materials last as long as possible."

Heavy duty filters

Meta-Aramide: the choice for race car drivers and the asphalt industry

Meta-Aramide filters are specially developed for dry processes, as long as there is no hydrolysis or oxidizing media. The material is also used in firefighter suits and race car driver clothing because of its resistance to high temperatures and wear. In the asphalt industry, we especially recommend Meta-Aramide filters for the production of new asphalt because the processes are relatively clean and dry.

|

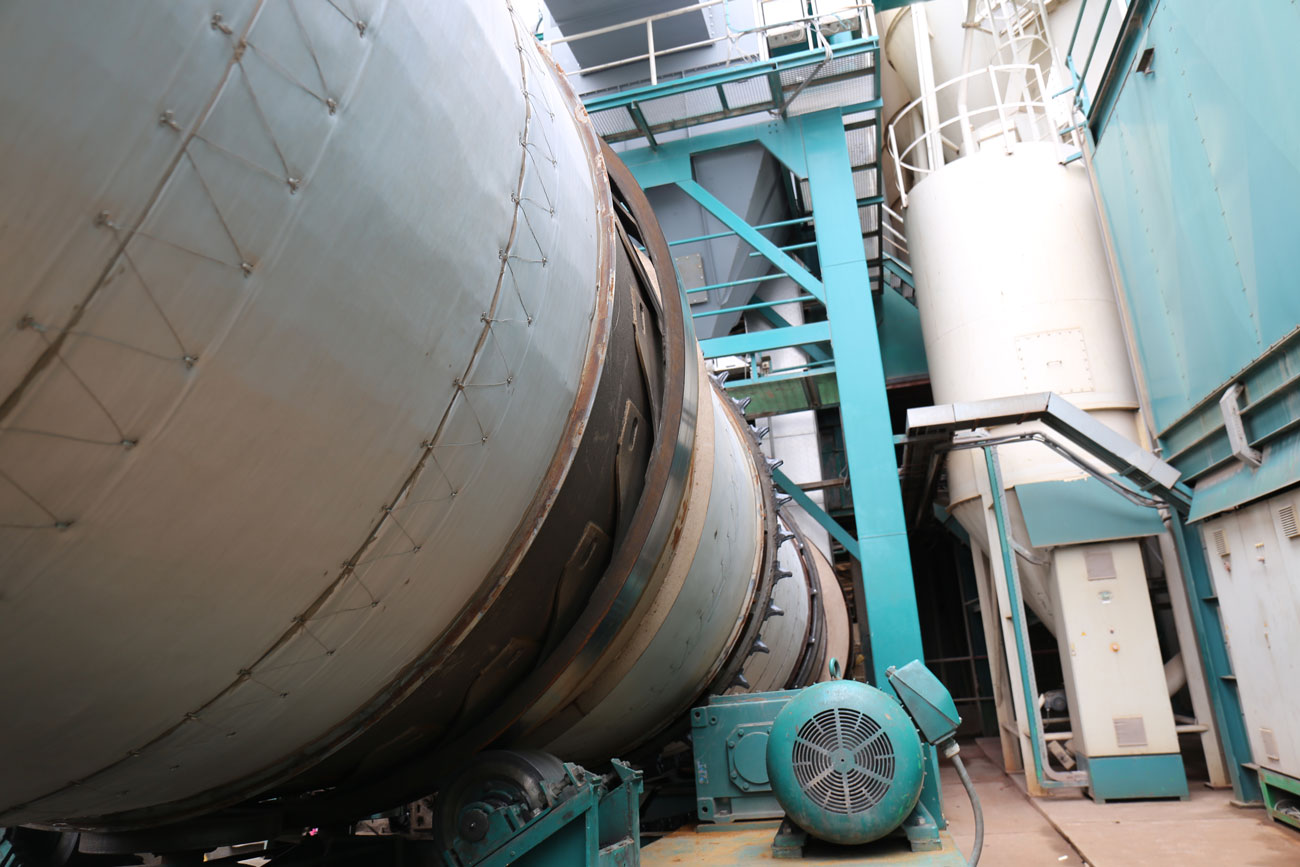

Vlint has connected the dust extraction system (right) to the mixing drum (left) of TME, equipped with Meta-Aramide filters.

|

In the hall of Tosec Machinebouw & Engineering, the parent company of TME, work is being done on a new drying drum.

|

"Vlint's advice has contributed to a longer lifespan of the dust extraction filters."

Nomex: for sustainable asphalt

TME, a producer of concrete and asphalt plants, has invested in Nomex filters with the help of Vlint. The deputy director of TME, Jan Boom, points out that new asphalt today must consist of at least 60% recycled material. "To properly mix old and new materials into a homogeneous whole, we heat installations much higher than before, sometimes up to 300 degrees." Despite these increased temperatures, Boom emphasizes that Vlint's advice has contributed to a longer lifespan of the dust extraction filters. "These have not been replaced in seven years."

Read the success story: "High temperature dust extraction at TME"

Teflon: a versatile material for demanding applications

When more is required than Meta-Aramide can offer, there is polytetrafluoroethylene, better known as PTFE or Teflon. This versatile material comes with a price tag, but it can handle high temperatures, moisture, acids, bases, and oxidation. It has been successfully used in an installation at Jansen Recycling BV in Son, Brabant, where old tar-containing asphalt is cleaned to prevent harmful Polycyclic Aromatic Hydrocarbons (PAHs). The cleaned asphalt can be used as secondary building material. Schipper explains that this process requires Teflon because the filter material is not only exposed to high temperatures but also to moisture and acidic substances.

|

Jansen Recycling BV, classification of the cleaned material for sustainable reuse in concrete production.

|

|

Improved filter cages prevent cracking

The only downside of Teflon is that it is relatively sensitive to mechanical stress. When Teflon filters are pulled too hard over the filter cages after cleaning, this can lead to cracking in the long term. To address this problem for the large bag house of PreZero (Suez), consisting of 1024 filters, Vlint designed special filter cages. These new cages have longitudinal wires that are closer together. According to Pim Vis, the project coordinator of PreZero, this is a sustainable solution. "Due to the new longitudinal wires, the filter cloth is less drawn into the cage, resulting in less friction. Vlint's Teflon filters will last for years this way."

"The modification proposed by Vlint for the small bag house has resulted in significant cost savings."

|

PPS filters prevent annual replacement due to extreme stress

Within the installation, there is also a small bag house responsible for removing dust released during the cooling of the cleaned product. In this environment, the filters must be highly resistant to high levels of water vapor. Initially, Teflon filters were also chosen here. They performed well, but due to the extreme stress, they still had to be replaced annually. "That was an expensive issue because Teflon is not only the best material but also the most expensive," explains Olaf Schippers.

Therefore, Vlint proposed a cost-effective alternative: filters made of polyphenylene sulfide, also known as PPS. This material is also versatile, with the only weakness being its susceptibility to oxidation. PreZero's project coordinator, Pim Vis, is extremely satisfied with the new filters. "The modification proposed by Vlint for the small bag house has resulted in significant cost savings. It shows that Vlint is genuinely committed to finding solutions that are both efficient and cost-effective for the customer."

|

Solutions that make an impact

For both the asphalt industry and other sectors, there are hundreds of types of filters on the market. As a result, the ability to think proactively is becoming increasingly important. With its own laboratory research and years of experience in heavy-duty dust extraction processes, Vlint can often make a difference. This allows us to extend filter lifespans, reduce procurement costs, ensure compliance with safety regulations, and reduce emissions.

According to Olaf Schipper, Vlint is therefore an important partner for many manufacturing companies. "It often turns out that we can surprise our customers with customized and innovative solutions. This yields them a lot, both in terms of production process efficiency and costs. Not only in the asphalt industry but also in other sectors, such as food, pharma, and chemicals, Vlint makes its mark in this way."

Curious about what we can do for you?

At Vlint, we help our customers by first thoroughly analyzing the problem. Then, we create an effective action plan and implement it to properly solve the issue. Interested? Leave your contact details without obligation, and we will get in touch with you as soon as possible.

Fill in the contact form