07-07-2022

|

3 min reading time

Three misconceptions about pulsing dedusting filters

How do you optimally adjust pulse systems of dedusting systems? Intuitively, many manufacturing companies tend to pulse systems as hard and as often as possible. They think this will make filters cleaner and ultimately improve their performance. The opposite is true. We list the three most persistent myths about tuning pulse systems.

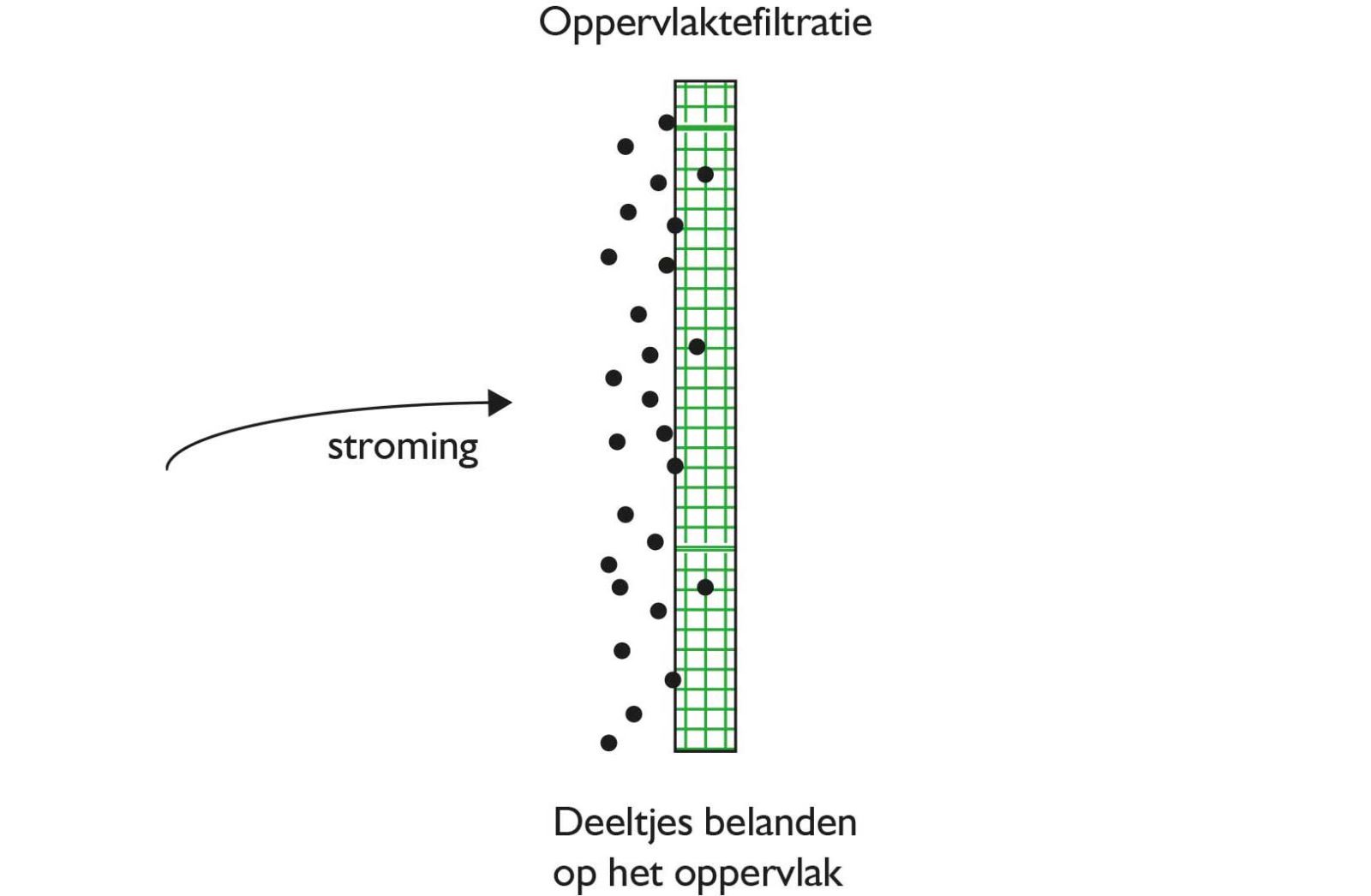

To understand the three misconceptions about pulses, it is important to know that almost all dedusting filters operate on the principle of 'surface filtration'. This means that the outer sides of filters trap much of the dust, so that a dust cake forms. This dust cake is essential to the filtration process, as it acts as an important filter layer./p>

Misconception 1: frequent pulsing reduces emissions from dedusting units

Frequent pulsing makes it difficult for the surface of a filter to build up dust cake. The absence of this extra filter layer gives small dust particles the chance to penetrate the filter medium. Anyone measuring the filter capacity of a dedusting unit in a laboratory sees this very clearly. Immediately after blowing away the dust cake when pulsing, dust monitors then display a small emission peak. As the dust cake then builds up, the emission decreases..

|

|

Misconception 2: frequent and loud pulses slow down the saturation process of filters

Again, the frequent blowing away of the dust cake is the reason why this statement does not hold true. The blowing away of the dust cake not only allows many small dust particles to pass through the filter, but also leaves several dust particles stuck deep inside the filter. Despite pulsing harder or even more frequently, these particles no longer succeed in getting out. The saturation of the filter has then already taken place..

Misconception 3: Frequent and hard pulsing makes filters last longer

This too is not correct. This is firstly due to the aforementioned problem with filter saturation. Saturation means that the ΔP, or pressure difference in front of and behind the filter, rises rapidly and does not disappear after pulsing. So-called stress occurs on the medium. Eventually, there is a high probability that saturation causes filters to crack or leak..

Frequent and loud pulsing also causes filters, especially filter bags, to move a lot. During the dedusting process, a filter is sucked against the filter basket and when pulsing, it pops out again. In the process, the filter moves along the longitudinal threads of the basket. If a filter is pulsed frequently and hard, it is frequently and hard pulled over the longitudinal threads. Eventually, this quickly damages filters.

|

|

Effective adaptations and solutions

Our specialists will be happy to help you fine-tune the system. We match the filter type, pulse time and product to be filtered and determine the critical limit for the differential pressure of a filter. We then switch on the dedusting system and measure how long it takes to reach the critical limit.

Based on this test, the installation is adjusted so that pulsing takes place exactly before the moment the installation crosses this limit. This minimises the amount of pulsing required. The result: longer filter service life, less downtime due to switching, compressed air savings and reduced emissions.

|

10 tips for life extension of dedusting filters

Want to know more about pulse systems and extending the service life of dedusting filters? Download the free whitepaper from Vlint's experts with 10 pieces of advice on extending service lives. In an overview with 10 practical recommendations, Vlint's experts show you how to extend filter service lives cheaply and efficiently. In the whitepaper, you can read how to:

- select the right filter medium;

- filters can be calendared or impregnated so that filters do not become saturated;

- guarantees that filters are resistant to abrasive substances;

- prevents the pressure difference from increasing too much;

- can adjust or modify filter systems so that filters are loaded correctly;

- pulse systems can be adjusted to extend filter service lives.

Download white paper

Would you like advice on adjusting your dedusting system?

Get in touch with our experienced team, we are happy to help you so you can be assured of the best possible solution.

Contact us op